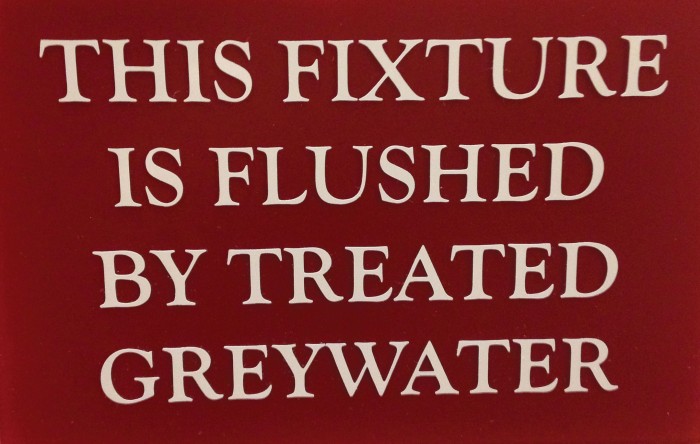

Townes Science Center toilets may look a little different recently. Notice the sign over the toilets explaining that the water in the fixture is “treated greywater?”

Although the signs are new, they represent a sustainability campaign dating back to 2008.

The water in the toilets has been treated on-site by a small-scale wastewater treatment facility called the Living Machine housed in the greenhouse next to the Science Center.

This machine works by mimicking natural tidal wetlands. Water flushed from toilets and water fountains in the Townes Science Center, the PAC, the Chapel, Furman Hall, and even Cherrydale Alumni House flow into the Living Machine via underground pipes. This wastewater then comes in to one of six holding cells in the system. The water is naturally filtered by plants, gravel and microbes as it travels through the cells. By the end of the process the water is run through fine microbe filters, treated with chlorine tablets and finally passes through an ultraviolet light to ensure that it is of a high enough quality.

The Living Machine has been on campus and has been filtering water since the Science Center was renovated in 2008. However, the treated water has only recently been able to be pumped back into the Science Center toilets as “reuse,” or greywater.

According to Jeff Redderson, assistant vice president of Facilities Services, there were a couple of hurdles to overcome in getting the system to pump the treated greywater back into the Science Center’s toilets. One hurdle came from theSouth Carolina Department of Health and Environmental Quality.

“Initially they wanted us to only run the treated water to the sewer so they could evaluate the quality,” Redderson said.

The water treated by the Living Machine has been tested and it actually exceeds state water quality standards.

A second, larger hurdle required changing the infrastructure surrounding the machine. The initial underground pumping system had to be replaced in order for the treated water to flow back into the toilets in the Science Center. The project to replace the pumps cost approximately $40,000.

As of last December, the pumps have been fully operational and the toilets have been using internally treated greywater instead of city water.

In addition to using water more efficiently, the greywater system provides an economic benefit. Using greywater that has been treated internally in toilets cuts some of the costs associated with buying city water.

According to Jim Aldridge, the man who monitors the Living Machine, the machine currently treats 3000 gallons of water a day. The tank has the capacity to treat 5000 gallons in a 24 hour period.

Yancey Fouche, associate director of the Shi Center for Sustainability, noted the importance of the greywater in toilets to Furman’s sustainability goals.

“Sustainability planning at Furman is governed by Sustainable Furman, a master plan developed with cross-campus input and approved by our Board of Trustees in 2009,” Fouche said. “The Living Machine project specifically helps us realize that plan in several ways.”

Treating wastewater internally with the Living Machine and then using that water again in toilets helps improve building energy efficiency, reduce our greenhouse gas inventory and generally maintains Furman’s reputation as a leader in sustainability.

Companies and peer institutions have visited Furman specifically to see the Living Machine and learn about how it works. According to Redderson, Furman houses the first Living Machine in all of South Carolina. Furman is also one of a very small number of universities that house comparable in-house wastewater treatment facilities.